In an era where efficiency and cost control define competitive manufacturing, automating non-woven folding processes isn’t just an upgrade—it’s a necessity. This article breaks down how investing in automated folding machines can reduce labor costs by up to 40% while delivering rapid ROI. We’ll provide actionable formulas, real-world examples, and hidden savings most manufacturers overlook.

Manual vs. Automated Labor Costs:

Compare hourly wages for manual folding operators (e.g., 20–30/hour) vs. automated systems requiring only 1–2 technicians for oversight.

Hidden Labor Expenses:

Include training, turnover, human error (e.g., material waste from inconsistent folds), and OSHA compliance risks.

Industry Trends:

Rising minimum wages and labor shortages driving demand for automation.

Scenario Analysis:

Example: A mid-sized PPE manufacturer with 10 manual folding stations:

Manual Process: 10 workers x 25/hour x 8hours=∗∗2,000/day**.

Automated Process: 2 technicians x 30/hour x 8hours=∗∗480/day**.

Daily Savings: 1,520(76 364,800 (240 workdays).

Scaling with Demand:

Automated non-woven folding machine handles surges without hiring/training new staff (e.g., pandemic-driven PPE spikes).

ROI Formula:

Variables to Include:

Machine Cost: 50,000–200,000 (varies by speed, customization).

Net Annual Savings: Labor savings + reduced waste + energy efficiency gains.

Payback Period: Typically 12–18 months for mid-range machines.

Example Calculation:

Machine cost: $120,000.

Annual labor savings: $364,800.

Reduced material waste: $15,000/year (from precise folding).

Energy costs: +5,000/year(offsetbysavings).∗∗NetAnnualSavings∗∗:364,800 + 15,000−5,000 = **374,800 - 120,000} \times 100 = 212% ]

Payback Period: ~4 months.

(Expand the value proposition)

Faster Production Speeds:

Automated machines fold 200–500+ pieces/minute vs. 30–50 manually.

Reduced Downtime:

Advanced sensors prevent jams and misfolds (vs. manual error correction).

Space Optimization:

Compact automated systems free up floor space for other processes.

Quality Consistency:

Eliminate customer returns due to defective folds.

Company: A hygiene products supplier in Texas.

Challenge: Struggling with 15% labor turnover and 20% waste from manual folding.

Solution: Installed a servo-driven folding machine with AI-powered defect detection.

Results:

Labor costs reduced by 42% in 6 months.

Waste cut by 30% (saving $50,000 annually).

ROI achieved in 11 months.

Key Features to Prioritize:

Adjustable Fold Patterns: Handle diverse products (masks, wipes, filters).

Energy-Efficient Motors: Lower long-term OPEX.

User-Friendly Interface: Minimize technician training time.

Ask Your Supplier:

Does the machine include predictive maintenance tools?

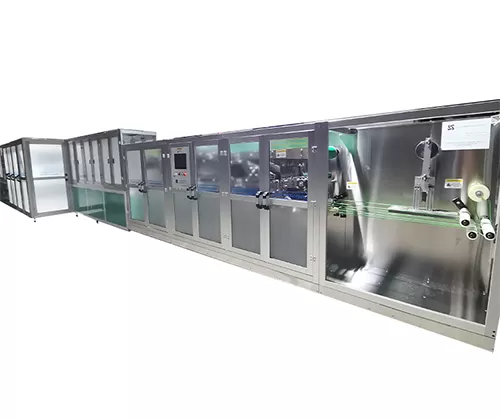

Can it integrate with existing production lines?

Adapt to Market Shifts:

Reprogram machines for new products (e.g., switching from medical masks to eco-friendly packaging).

Software Upgrades:

IoT-enabled machines improve over time with remote updates.

Automated folding machines aren’t just a cost-cutting tool—they’re a growth accelerator. With ROI achievable in under a year and labor savings exceeding 40%, the question isn’t if you should automate, but how soon.