The textile industry, a crucial sector in the global economy, has undergone significant transformations over the years. Among the many innovations that have driven this change, the introduction of the bed cover making machine stands out as one of the most impactful advancements. These machines have revolutionized the production process, making it faster, more efficient, and more environmentally friendly. In this article, we will explore how bed cover making machines are reshaping the textile landscape by enhancing productivity, improving fabric quality, and providing greater flexibility for manufacturers.

One of the most significant benefits of the bed cover making machine is the improvement in production efficiency. Traditional methods of bed cover manufacturing were highly labor-intensive, requiring multiple manual processes such as cutting, stitching, and finishing. This not only consumed a significant amount of time but also increased the risk of human error, resulting in inconsistent product quality and higher labor costs.

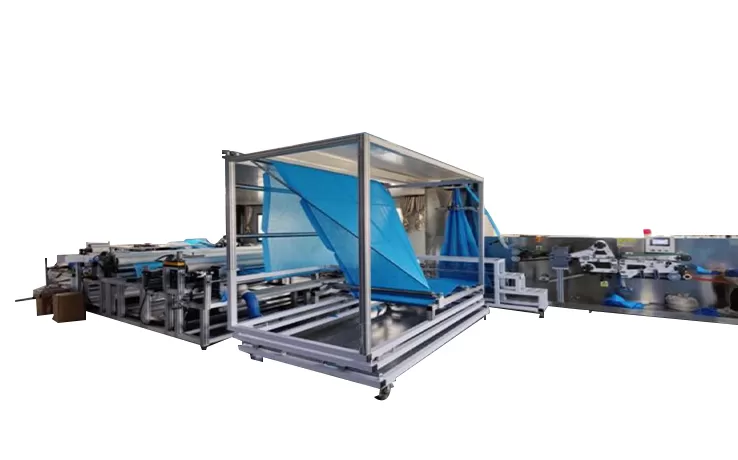

With the advent of automated bed sheet making machine, the entire production process has been streamlined. These machines can handle a variety of tasks, from cutting fabric to stitching the final product, all with minimal human intervention. Some of the most advanced models feature automatic fabric feeding, cutting, and stitching systems, which allow for high-speed, continuous production without the need for frequent stops. This level of automation reduces production time drastically, allowing manufacturers to meet growing market demands without compromising quality.

Furthermore, these machines come equipped with advanced control systems that ensure precise measurements, consistent stitching, and minimal fabric wastage. The result is not only a faster production cycle but also higher yields, which is crucial in an industry where profit margins are often tight. Manufacturers who invest in bed cover making machines can produce more units in less time, thereby improving their overall productivity and profitability.

In the textile industry, maintaining high-quality standards is essential to staying competitive in a crowded market. Quality control is one of the most significant challenges for traditional manual methods of bed cover production, as variations in stitching, fabric cutting, and finishing can lead to defects or inconsistencies in the final product. This is where bed cover making machines offer a clear advantage.

These machines utilize advanced technologies like computerized pattern recognition, digital fabric control, and automated stitching systems, ensuring that every bed cover produced meets the highest quality standards. With precise control over each step of the process, the machines eliminate the inconsistencies that can arise from manual handling. The result is a product that is uniform in size, shape, and stitching, with a clean, professional finish.

Additionally, many modern bed cover making machines are designed to handle a wide range of fabrics, including cotton, polyester, and blends. This versatility allows manufacturers to create different textures and finishes without needing to adjust the machine significantly, further improving the quality of the product. With less variability in the production process, manufacturers can guarantee that their bed covers meet both industry standards and customer expectations.

Another way that bed cover making machines have revolutionized the textile industry is by providing manufacturers with greater flexibility and customization options. As consumer demand shifts toward personalized products, there is an increasing need for manufacturers to offer a variety of designs, sizes, and colors. Bed cover making machines cater to this trend by allowing for quick adjustments to the production process to meet specific customer requirements.

For instance, many machines today come with customizable stitching patterns, enabling manufacturers to create unique designs that stand out in the marketplace. Whether it’s a simple quilted pattern or a more intricate embroidered design, bed cover making machines can easily accommodate these variations without slowing down production. This ability to offer customized designs not only helps businesses differentiate themselves from competitors but also enables them to tap into niche markets that value unique, made-to-order products.

Moreover, these machines are capable of producing a wide range of bed cover sizes, from single to king-sized covers. With the push of a button, manufacturers can adjust the machine settings to accommodate different fabric widths and dimensions, allowing them to offer tailored solutions for various customer preferences. This level of flexibility enables manufacturers to cater to both bulk orders and smaller, custom requests, making it an essential tool for staying competitive in today's diverse market.

The introduction of the bed cover making machine has truly revolutionized the textile industry. By improving production efficiency, ensuring high-quality standards, and offering customization options, these machines have empowered manufacturers to meet the growing demand for quality and versatility in bed cover production. As technology continues to evolve, we can expect even more advanced features and capabilities, further transforming the industry. For textile businesses, investing in these machines is no longer a luxury—it's a necessity to remain competitive and meet the demands of today's fast-paced market.